Consciously or otherwise, humans have always feared the unknown. And, we’re never fully ready to meet what will come in the future.

Creating

Self-Optimizing plants

Are your AI efforts in your manufacturing units failing to take off?

If yes, it must be because of one simple reason. The stakes in industrial/manufacturing companies are far higher than in other commercial businesses – and industrial AI is too nascent to be entrusted with them.

There are several barriers that you need to overcome to make the best use of your AI, like:

Bad quality training data

Any algorithmic intervention needs quality data to be successful. However, data produced in manufacturing units often ends up being biased and skewed due to operational conditions. Often, data is produced by various systems in different formats, which may not be suitable for analytics, and requires extensive reprocessing.

Interoperability

Manufacturing plants often work with different kinds of systems that do not communicate with each other and may sometimes be incompatible with each other. Developing data models to scale under these situations would be difficult.

Testing costs

It costs time and money to test AI systems on actual systems, such as operational manufacturing lines, industrial equipment, and warehouses. Implementing simulation environments is necessary for effective teaching and testing.

Lack of talent

Any AI project needs a dedicated, interdisciplinary team of Data Scientists, ML engineers, software architects, and BI analysts for successful implementation and maintenance. However, today, there is a dearth of talent in AI and Algorithmic technology dedicated to the manufacturing sector.

Opporture acts as your technical wing and solves all these issues through:

Opporture’s expert AI consultants help you push the boundaries of operational excellence and leverage your algorithms to the best of their ability.

We provide:

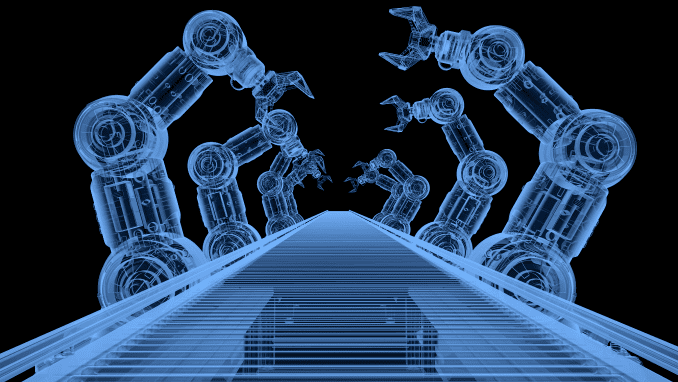

Use annotated data to train and validate robotic navigation systems and enable them to interact safely with the production environment.

Train your algorithm to anticipate equipment failures and issues before they occur, and notify maintenance teams to respond to them accordingly. Predict maintenance, repairs, and replacements and keep your systems operational for a longer time.

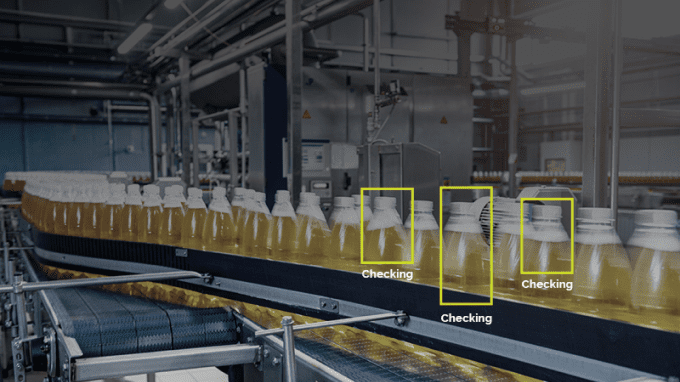

Spot manufacturing defects on the production line, keep track of inventory, guide manufacturing robots for automated product assembly without bumping into each other, perform quality and inspection checks, and ensure staff safety with annotated computer vision.

Know more about what we enabled in Industrial AI:

Consciously or otherwise, humans have always feared the unknown. And, we’re never fully ready to meet what will come in the future.

Talk to us!

Copyright © 2023 opporture. All rights reserved | HTML Sitemap